Discover Our Range of Fiber Optic Products

HOLIGHT, a leading Fiber Optic Patch Cord manufacturer in China, invites you to explore the future of high-speed data transmission. We specialize in diverse categories such as Waterproof Patch Cord, Standard Patch Cord, MPO/MTP Patch Cord, Special Patch Cord and Fiber Pigtail. No matter what style of fiber optic patch cord you want, based on our extensive experience, we can manufacture it according to your exact demand.

Popular Products Based on Feedback from Our Clients

At HOLIGHT, it’s all about you and your fiber optic needs. We’ve been in the business for over a decade, and our focus is on providing solutions that work best for you. Whether you’re looking for waterproof patch cords, multi-core options, or Grade A High-Quality patch cords, we’re here to tailor-make them just for you. Your satisfaction is our top priority.

- Tailored Just for You

Our customization services are designed to meet your unique needs. We can adapt our products based on your specific drawings and requirements.

- Read More

- No Minimum Orders

You’re not bound by minimum order quantities when it comes to our regular products. However, for specialized optical cables, we usually start at 500 to 1000 meters. Our business team can provide you with more detailed information.

- Read More

- Fast Production

We’re equipped to produce up to 1 million standard Terminations every month. You can expect your standard products to be ready in just 4-6 business days.

- Read More

- Your Privacy Matters

Your privacy and intellectual property are of utmost importance. We have stringent confidentiality agreements in place to safeguard your sensitive information.

- Read More

- We're Here for You

We’re dedicated to being responsive. Whenever you have questions or requests, count on us to provide quick and efficient communication and assistance. Your satisfaction is our priority.

- Read More

- Dedicated To Quality

We prioritize your satisfaction with top-tier products and services that surpass industry standards, providing lasting solutions that exceed your expectations.

- Read More

The Ultimate Guide to Fiber Optic Patch Cords: What You Must Know

The fiber optic patch cord, often simply called patch cord, is a type of cable that consists of optical fibers and is used to connect and transmit data between devices in a fiber optic network. These cords typically have connectors at both ends that can be easily plugged into devices like routers, switches, and transceivers.

The primary purpose of a fiber optic patch cord is to establish a temporary or permanent connection between devices, ensuring the efficient transfer of data through optical signals. These cords come in various types and configurations to suit different applications, including single-mode and multimode fibers, different connector types (e.g., LC, SC, ST, FC, MTRJ, MPO/MTP, MU, E2000), and various lengths to accommodate specific network needs.

Fiber Optic Patch Cord is known for its high-speed data transmission, reliability, and efficiency, making it a crucial player in industries ranging from telecommunications to healthcare and aerospace.

Whether you’re importing fiber optic patch cords for your projects or the local market, this guide is your go-to resource. It’s designed to simplify your patch cord procurement process and arm you with the knowledge you ne

Table of Contents

1.What is the Component of Fiber Optic Patch Cord?

2.What are the International Testing Standards for Fiber Optic Patch Cord?

3.What are the Testing Standards for Fiber Optic Patch Cord Ferrule End Faces?

4.Understanding 3D Testing for Fiber Optic Patch Cords and Relevant Standards

5.Varieties of Fiber Optic Patch Cords Available in the Market

6.Key Considerations When Buying Fiber Optic Patch Cords

7.How to Pick the Right Fiber Optic Patch Cord Supplier/Manufacturer?

8.What is the Production Process of Fiber Optic Patch Cords?

9.How to Maintain and Clean Fiber Optic Patch Cords?

10.Versatile Applications of Fiber Optic Patch Cords Across Various Industries

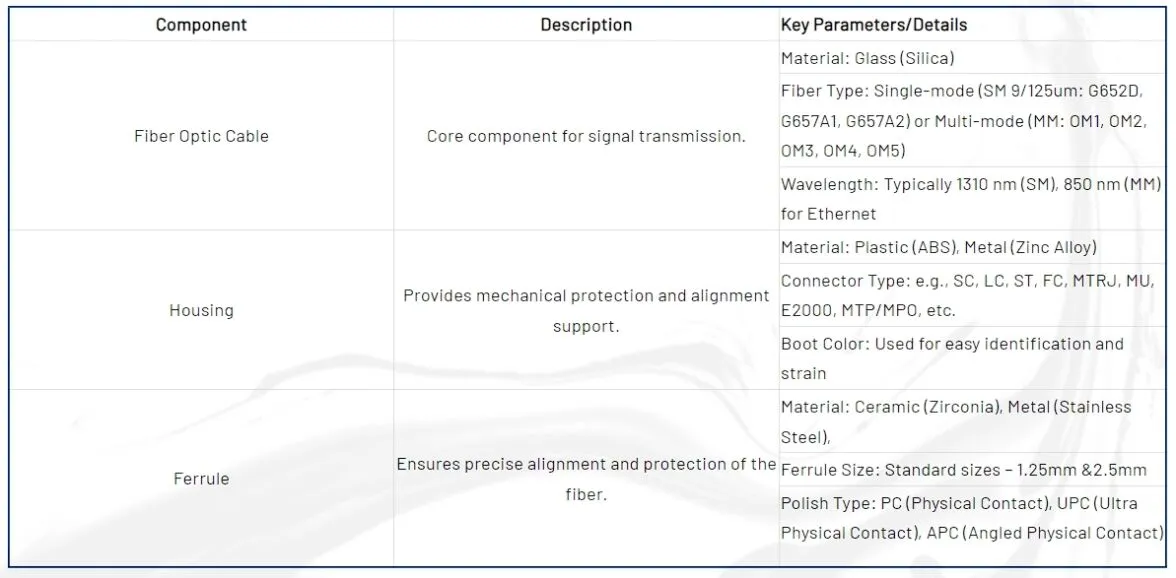

The fiber optic patch cord is composed of three essential components: the fiber optic cable, housing, and ferrule. For a more in-depth understanding of these components and their functions, we invite you to explore our detailed blog post.

.

Superior Corrosion Resistance: Titanium stands up exceptionally well to seawater, making it the choice material for marine applications.

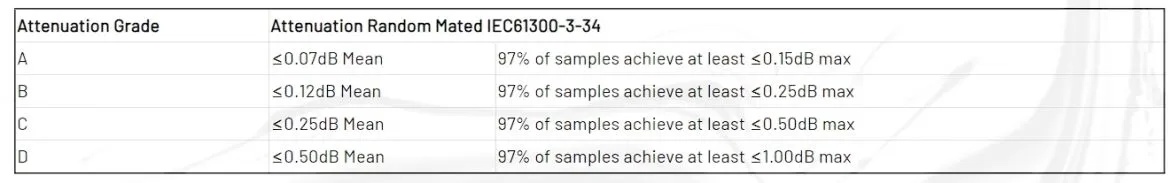

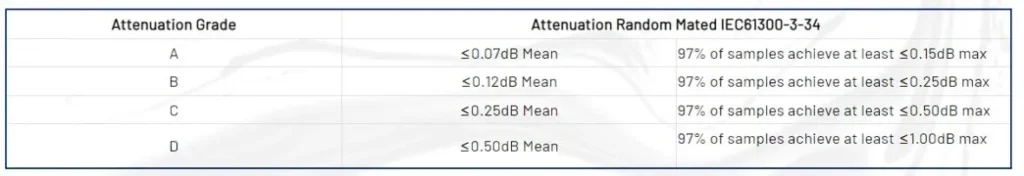

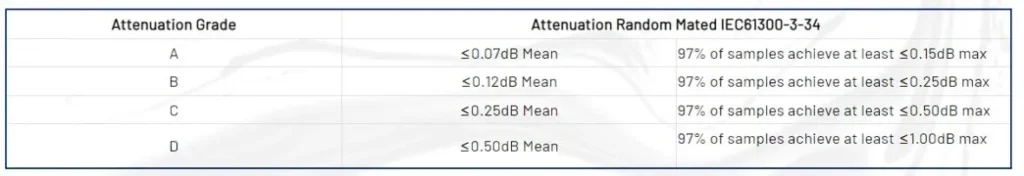

The International Testing Standards for Fiber Optic Patch Cords encompass various attenuation grades, with Grade C being the most popular among clients due to its balanced performance and cost-effectiveness. Grade B is chosen by some clients for higher data demands, while Grade D is an option for those seeking more budget-friendly solutions for their projects.

HOLIGHT is capable of providing patch cords conforming to all these grades, ensuring compatibility with clients’ specific requirements.

Here’s a more concise summary:

.

Defects like scratches, pits, and chips are examined and have different acceptability criteria based on their location and size.

Cleaning: The standard emphasizes the importance of cleanliness and provides guidelines for cleaning methods. Any contamination can cause signal loss or reflection, leading to reduced performance. It’s crucial to clean the end faces before each connection.

Microscopic Inspection: A fiber microscope, typically with magnifications ranging from 200x to 400x, is used to inspect the end face. The microscope helps in identifying defects that can’t be seen with the naked eye.

Rejection Criteria: Depending on the zone (core, cladding, etc.) and the type (scratch, pit, etc.), different defects have different size thresholds that determine whether a connector is acceptable or needs to be rejected or cleaned.

To ensure optimal performance, technicians and engineers involved in fiber optic installations and maintenance should be well-versed in these standards and should use the proper tools and techniques for inspection and cleaning.

Fiber optic patch cord ferrule end faces are critical components that must meet precise cleanliness and quality standards to ensure optimal performance. The quality and cleanliness of the ferrule end faces directly impact the transmission of light signals and overall system performance. Standards for the examination and testing of these end faces have been established by international organizations.

The primary standard used for testing and inspecting fiber optic patch cord ferrule end faces is the IEC 61300-3-35 standard, established by the International Electrotechnical Commission (IEC). This standard provides guidelines for the visual inspection and cleaning of single-mode and multimode fiber optic connectors and jumper assemblies.

Here are some key highlights from the IEC 61300-3-35 standard:

Visual Inspection Criteria: The end face of the fiber optic connector is divided into zones (core, cladding, adhesive, and contact), and each zone has its specific inspection criteria.

The 3D test for fiber optic patch cords typically refers to a test that evaluates the physical characteristics and performance of a fiber optic connector in three dimensions: length, width, and depth. This test aims to ensure that the connector is manufactured to precise specifications and meets the required industry standards.

During the 3D test, specialized equipment is used to measure various aspects of the connector, including:

End face Geometry: This assesses the connector’s physical features such as the shape, curvature,

and smoothness of the connector’s end face. Any irregularities can impact signal transmission.

Ferrule Diameter and Concentricity: It measures the diameter of the ferrule (the component that holds the fiber) and checks its alignment within the connector. Proper alignment is crucial for minimizing signal loss.

Ferrule Length: This measures the length of the ferrule, ensuring it meets the required specifications.

Apex Offset: It evaluates the alignment of the fiber core within the ferrule to ensure it is centered correctly.

Fiber Height: This measures the height of the fiber endface within the ferrule, which can impact its connection with other fibers.

The 3D test for fiber optic patch cords typically refers to a test that evaluates the physical characteristics and performance of a fiber optic connector in three dimensions: length, width, and depth. This test aims to ensure that the connector is manufactured to precise specifications and meets the required industry standards.

During the 3D test, specialized equipment is used to measure various aspects of the connector, including:

End face Geometry: This assesses the connector’s physical features such as the shape, curvature,

and smoothness of the connector’s end face. Any irregularities can impact signal transmission.

Ferrule Diameter and Concentricity: It measures the diameter of the ferrule (the component that holds the fiber) and checks its alignment within the connector. Proper alignment is crucial for minimizing signal loss.

Ferrule Length: This measures the length of the ferrule, ensuring it meets the required specifications.

Apex Offset: It evaluates the alignment of the fiber core within the ferrule to ensure it is centered correctly.

Fiber Height: This measures the height of the fiber endface within the ferrule, which can impact its connection with other fibers.

In addition to the traditional LC, SC, FC, and ST patch cords, the fiber optic patch cord market offers a diverse range of options, typically organized into five distinct categories. The rapid expansion of 5G infrastructure has led to a notable surge in the demand for waterproof patch cords. Here’s an overview:

Waterproof Fiber Patch Cord: Noteworthy examples encompass FullAXS LC Patch Cord, Optitap SC/APC Patch Cord, Mini Waterproof, ODC Patch Cord, ODVA LC/SC/MPO Patch Cord, and PDLC Patch Cord.

Uniboot Fiber Patch Cord: Prominent choices include Uniboot LC Patch Cord and Uniboot SC Patch Cord.

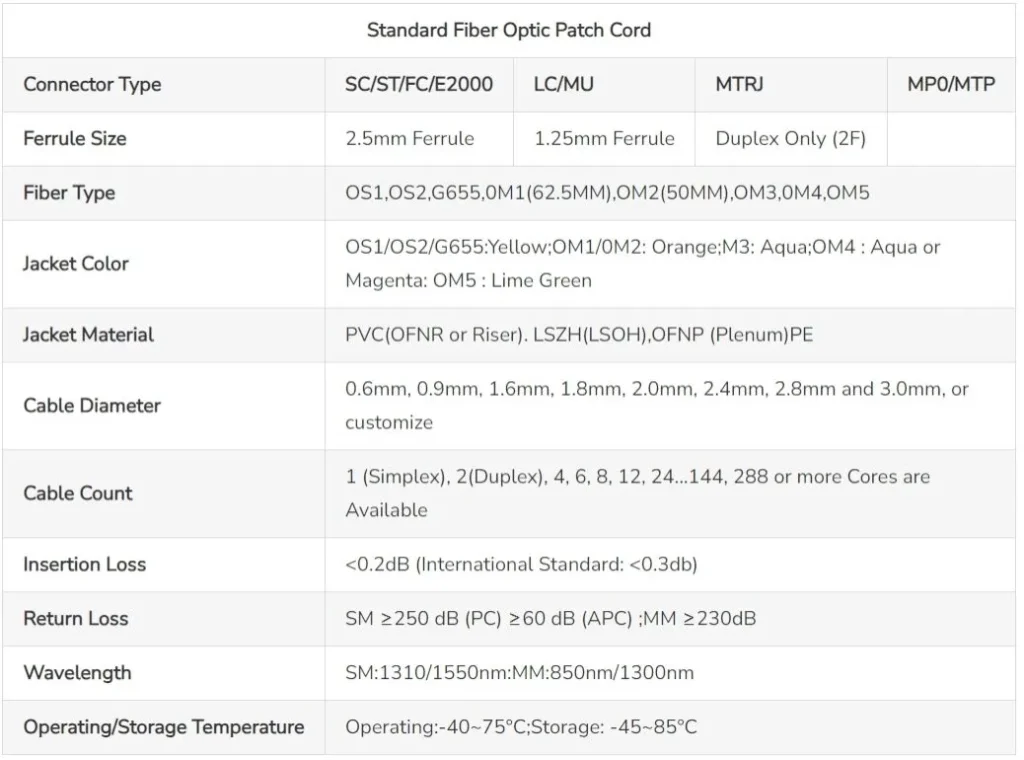

Standard Fiber Patch Cord: This category encompasses widely used connectors, such as LC, SC, ST, FC, MU, MTRJ, E2000, among others.

MPO/MTP Fiber Patch Cord: Varieties include Ribbon MPO/MTP Patch Cord, MPO/MTP Trunk, and Breakout MPO/MTP Patch Cord.

Special Fiber Patch Cord: This versatile category includes SMA, DIN, LX5, CS, Mode Conditioning Patch Cord, Armored Patch Cords, and more.

HOLIGHT offers the flexibility to customize patch cords according to clients’ specific requirements, ensuring a tailored solution for diverse networking needs.

.

Selecting the perfect supplier or manufacturer for your fiber optic needs is a critical decision that can significantly impact your project’s success. Here’s a guide on what to consider:

Quality Assurance: Choose a supplier committed to rigorous quality control processes and standards. This ensures you receive products that not only meet but often exceed your expectations.

Expertise and Experience: Opt for a supplier with extensive experience in fiber optic production. This expertise demonstrates a deep understanding of the material, enabling them

to offer expert advice and customized solutions.

Product Variety: A wide product range is a sign of a supplier’s ability to meet diverse needs. Whether you need fiber adapters, attenuators, terminal boxes, or custom designs, having plenty of options is advantageous.

Customization: Seek a supplier that provides customization options to tailor products to your specific requirements, ensuring they perfectly match your application.

Reputation and Reviews: Look for positive customer feedback and reviews. A strong industry reputation indicates reliability, consistency, and customer satisfaction.

Collaborative Approach: An ideal supplier collaborates closely with customers, involving them in the design and manufacturing process to create tailored solutions.

Production Capacity: Assess the supplier’s production capacity to ensure they can meet your project’s volume and timelines. A capable supplier guarantees timely delivery without compromising quality.

Transparency and Communication: Effective communication is essential. A supplier who maintains transparency throughout the purchasing process ensures a smooth experience.

Logistics and Delivery: Consider a supplier with reliable logistics and efficient delivery processes to ensure your fiber optic products arrive safely and on time.

Environmental Responsibility: Opt for suppliers that prioritize sustainability and environmental responsibility in their manufacturing processes.

By evaluating these factors, you can confidently choose a fiber optic product supplier or manufacturer that aligns with your needs and values, ultimately contributing to the success of your project.

Selecting the perfect supplier or manufacturer for your fiber optic needs is a critical decision that can significantly impact your project’s success. Here’s a guide on what to consider:

Quality Assurance: Choose a supplier committed to rigorous quality control processes and standards. This ensures you receive products that not only meet but often exceed your expectations.

Expertise and Experience: Opt for a supplier with extensive experience in fiber optic production. This expertise demonstrates a deep understanding of the material, enabling them to offer expert advice and customized solutions.

Product Variety: A wide product range is a sign of a supplier’s ability to meet diverse needs. Whether you need fiber adapters, attenuators, terminal boxes, or custom designs, having plenty of options is advantageous.

Customization: Seek a supplier that provides customization options to tailor products to your specific requirements, ensuring they perfectly match your application.

Reputation and Reviews: Look for positive customer feedback and reviews. A strong industry reputation indicates reliability, consistency, and customer satisfaction.

Collaborative Approach: An ideal supplier collaborates closely with customers, involving them in the design and manufacturing process to create tailored solutions.

Production Capacity: Assess the supplier’s production capacity to ensure they can meet your project’s volume and timelines. A capable supplier guarantees timely delivery without compromising quality.

Transparency and Communication: Effective communication is essential. A supplier who maintains transparency throughout the purchasing process ensures a smooth experience.

Logistics and Delivery: Consider a supplier with reliable logistics and efficient delivery processes to ensure your fiber optic products arrive safely and on time.

Environmental Responsibility: Opt for suppliers that prioritize sustainability and environmental responsibility in their manufacturing processes.

By evaluating these factors, you can confidently choose a fiber optic product supplier or manufacturer that aligns with your needs and values, ultimately contributing to the success of your project.

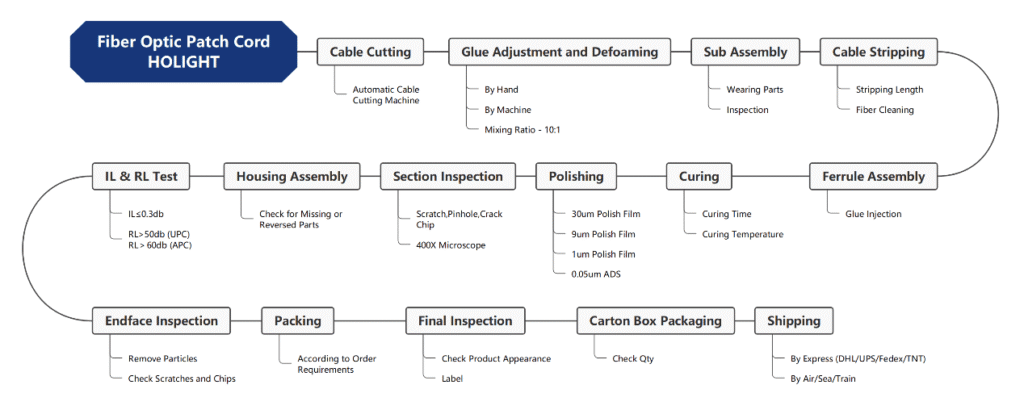

To ensure the manufacturing of premium fiber optic patch cords, HOLIGHT typically follows a well-defined production process. For additional insights and a more comprehensive understanding of our production procedures, we invite you to peruse our dedicated blog post on this topic.

Cable Cutting: The process starts with cutting the fiber optic cable to the required length, ensuring precision and accuracy.

Glue Adjustment and Defoaming: 353ND Epoxy is applied to secure the optical fibers within the connector. Special attention is paid to eliminating air bubbles, ensuring a stable connection.

Sub-Assembly: Various components, such as ring, stopper, spring or boots, are assembled onto the cable to provide mechanical protection and strain relief.

Cable Stripping: The protective coating or buffer surrounding the optical fibers is stripped off carefully to expose the bare fibers for termination.

Ferrule Assembly: Connectors, which include ferrules that hold the optical fibers, are assembled onto the prepared fiber ends. Precision alignment is essential during this step.

Curing: The adhesive used to secure the fibers and connectors is cured or set to ensure a stable and durable connection, often through the oven.

Polishing: The connector ferrules are polished to achieve a smooth and flat end face. This step is crucial for minimizing signal loss.

Section Inspection: The patch cords are inspected by the 400X microscope to identify any defects or issues that need correction. This quality control step ensures high standards are met.

Housing Assembly: Additional components, such as connector housing, are assembled onto the connector for protection and strain relief.

Insertion Loss and Return Loss Test(IL&RL Test): Each patch cord undergoes testing to measure insertion loss (signal loss during transmission) and return loss (reflection loss) to ensure it meets performance specifications.

End Face Inspection: The end faces of connectors are closely examined to verify they are free from defects, contamination, or scratches that could impact performance.

Packing: Patch cords are prepared for shipment or distribution by labeling them with relevant information, including length, type, and serial number.

Final Inspection: A comprehensive inspection ensures all quality and performance standards are met before the patch cords are ready for use.

Carton Box Packaging: The patch cords are packed into carton boxes for protection during shipping and storage.

Proper maintenance and cleaning of fiber optic patch cords are essential to ensure their optimal performance and longevity. Here are some tips for maintenance and cleaning:

Inspection: Regularly inspect patch cords for physical damage, such as bent or kinked fibers, broken connectors, or loose connectors. Damaged patch cords should be replaced promptly to prevent signal loss.

Cleaning Tools: Use appropriate cleaning tools, such as lint-free wipes, cleaning swabs, and isopropyl alcohol, to clean connector end faces. Avoid using materials that can leave residues or scratch the connectors.

Connector Protection: Always keep dust caps on unused connectors to prevent contamination. When not in use, store patch cords in a clean, dust-free environment.

Cleaning Procedure: When cleaning connector end faces, gently wipe in a straight line from the center to the outer edge. Avoid circular motions, as they can cause

scratches. Inspect the connectors after cleaning to ensure they are free of contaminants.

Cleaning Frequency: Clean patch cord connectors whenever you connect or disconnect them. Also, perform routine cleaning as part of your network maintenance schedule.

Inspection Tools: Consider using specialized fiber optic inspection tools, such as fiber scopes or microscopes, to inspect connector end faces closely for any contamination or damage.

Fiber optic patch cords find versatile applications across a wide spectrum of industries due to their high-speed data transmission, reliability, and efficiency. Here are some key industries where fiber optic patch cords are commonly used:

Telecommunications: Fiber optic patch cords form the foundation of modern telecommunications networks, facilitating high-speed internet, telephone, and television services, ensuring seamless global communication.

Data Centers: Data centers heavily rely on fiber optic patch cords for rapid data transmission between servers and storage systems. This technology is essential for managing the vast volumes of data generated in the digital age.

Healthcare: In the medical field, fiber optic patch cords are used for various applications, including endoscopy and laser surgery. They provide precise imaging and illumination in medical devices, enhancing diagnostic and treatment procedures.

Oil and Gas: Fiber optic patch cords are crucial for monitoring and controlling remote oil and gas facilities. They enable real-time data transmission, ensuring safety and operational efficiency.

Aerospace and Aviation: Fiber optic patch cords are utilized in aircraft and spacecraft for data communication and control systems. Their lightweight and robust properties make them ideal for aviation applications.

Military and Defense: The military relies on fiber optic patch cords for secure and high-speed communication, surveillance, and data transmission in challenging and rugged environments.

Broadcasting: Television studios and broadcasting companies use fiber optic patch cords for transmitting high-definition video and audio signals over long distances, ensuring top-quality broadcasts.

Automotive: Modern vehicles increasingly incorporate fiber optic patch cords for data communication within the vehicle’s systems and for high-speed data transfer in infotainment systems.

Industrial Automation: Manufacturers use fiber optic patch cords for precise control and monitoring in automated industrial processes. Their resistance to electromagnetic interference and harsh environmental conditions is invaluable in manufacturing environments.

Utilities: Fiber optic patch cords are essential for utilities companies to monitor and control power distribution, water treatment, and other critical infrastructure systems efficiently and reliably.

Education: Educational institutions leverage fiber optic patch cords to enhance internet connectivity and provide high-speed data access to students and faculty, supporting modern e-learning environments.

Finance: Financial institutions depend on fiber optic patch cords for secure and high-speed data transmission in trading and financial transactions, ensuring real-time market access.

Entertainment: Fiber optic patch cords enable high-speed internet access, supporting online gaming, video streaming, and various entertainment services with low latency and high bandwidth.

Research and Development: Fiber optic patch cords play a crucial role in various research fields, including physics, chemistry, and materials science, facilitating precise measurements and data transmission for experiments and studies.

In summary, fiber optic patch cords serve as indispensable components, providing essential connectivity and data transmission capabilities in numerous industries, from telecommunications to healthcare, aerospace, and beyond. Their versatility and reliability continue to drive their widespread adoption across various sectors, contributing to the efficiency and innovation of modern technologies and services.

Patch Cord and UTP (Unshielded Twisted Pair) Patch Cord are two commonly used types of cables in networking and telecommunications. They serve different purposes and have distinct characteristics. Here’s a comparison of these two types of patch cords:

FAQs

1. Can I customize my Fiber Optic Patch Cord?

Of course, customization is one of our characteristics, especially in customizing complex fiber optic jumpers, we have great advantages.

2. Can I use a single-mode patch cable for a multimode application, or vice versa?

Using a single-mode patch cable for a multimode application, or vice versa, is generally not recommended. These two types of fiber optic cables have different core diameters and characteristics, and they are optimized for different types of data transmission:

Single-Mode Fiber (SMF): Single-mode fiber has a much smaller core diameter, typically around 9 microns. It is designed to carry a single mode of light, allowing for longer-distance, high-speed data transmission. Single-mode fiber is commonly used for long-distance telecommunications and data transmission applications.

Multimode Fiber (MMF): Multimode fiber has a larger core diameter, typically around 50 or 62.5 microns. It can carry multiple modes of light simultaneously, making it suitable for shorter-distance applications within data centers and local area networks (LANs).

The key differences between these two types of fiber, particularly the core size, mean that they are not directly compatible. Using a single-mode patch cable in a multimode application or vice versa can result in significant signal loss, reduced performance, and data transmission issues.

To ensure optimal performance and compatibility, it’s essential to match the fiber patch cable to the type of fiber and application you are using. Using the correct cable type helps maintain data integrity and efficiency in your network or data transmission setup.

3. Are there any patch cords available with the PC connector?

The PC connector has been replaced with the UPC connector, which is an improved version. UPC connectors have a smoother surface finish achieved through extended polishing, resulting in better optical performance compared to the older PC connectors. So, we primarily offer UPC connectors for enhanced connectivity.

4. Can the standard fiber patch cables be used outdoors, and what happens if I use them outdoors?

Standard fiber patch cables are exclusively designed for indoor use. Utilizing them outdoors may result in premature cable damage and a decline in performance. For outdoor applications, we strongly recommend using our waterproof fiber patch cables, specially engineered to withstand outdoor conditions.

5. What Is the Lifespan of Fiber Optic Patch Cord?

The lifespan of a fiber optic patch cord typically ranges from 5 to 20 years, depending on various factors such as the quality of the cable, the environment in which it’s used, and how well it’s maintained. High-quality patch cords that are well-protected and used in controlled environments tend to have a longer lifespan, while those exposed to harsh conditions or subject to frequent bending and handling may have a shorter lifespan. Regular inspections and proper care can help extend the life of fiber optic patch cords.

6. What is the significance of the color of the fiber optic patch cable jacket?

Different colors are often used to distinguish between various types of fiber optic cables. For example, single-mode fiber cables may have a yellow jacket, while multimode cables could be orange. This color-coding helps technicians quickly identify the type of cable they are working with, as different applications may require different types of fiber.